Electric Motor Capabilities

Repair and Reconditioning

Machine Shop

Precision Machining

Motor Shaft Run-outs, Mituyo .001-.100 TIR dial indicator

Flame Spray Metalizing

Dynamic Rotor Balancing

Bearing and Bearing fit Measurement and Replacement

Shaft Fabrication and Modification

Lamination Fabrication - Un-stack and restack laminations, re-insulate coatings of lamination sheets and new laminations cut, punched and slotted to OEM Specs.

Welding

Finishing and Polishing

Machine Repair

Electrical

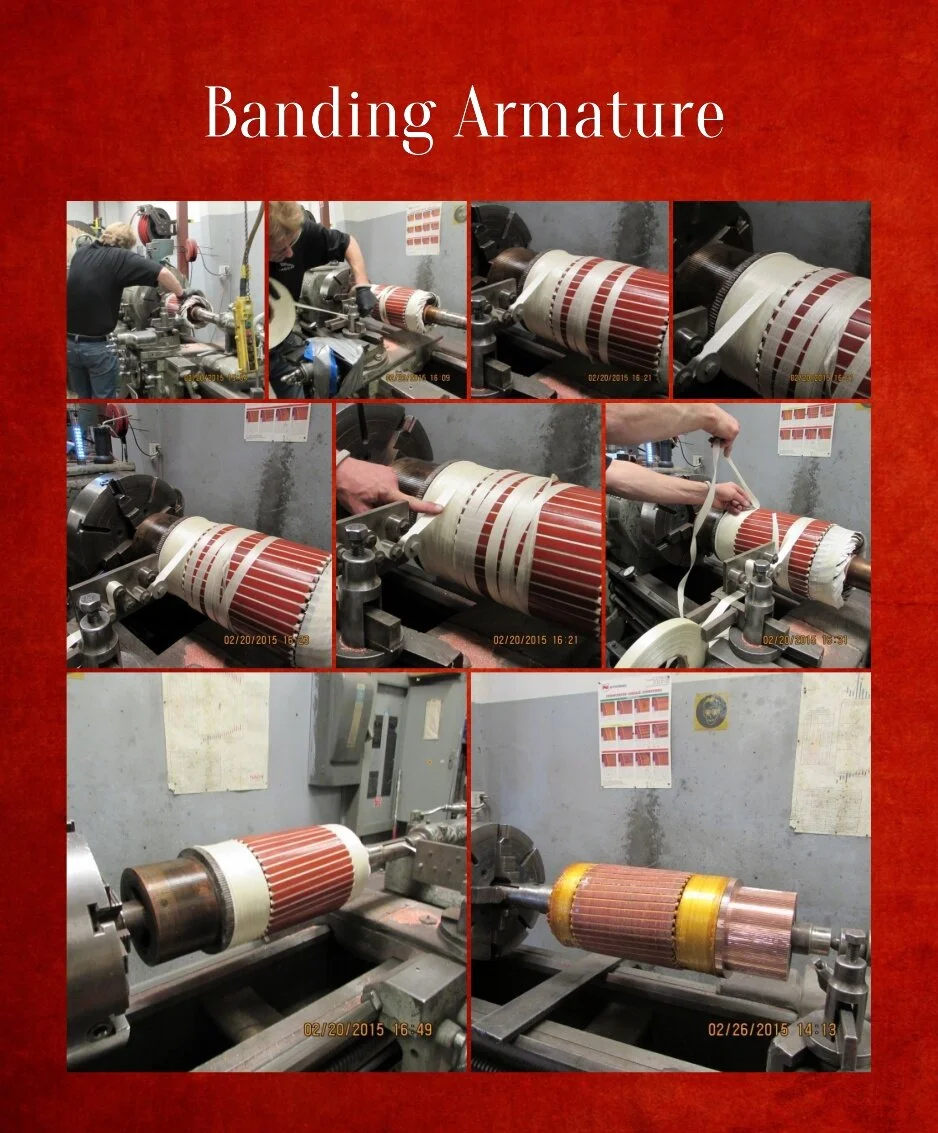

Armatures and Encoder Replacement

Stators, Rotors, Insulated Laminated Stacks and Wound Coil Service

Motor Rewind with Varnish Dip

Temperature Controlled and Environmental Bake-out Ovens

Synchronous AC Motors

AC,DC Motors and Generators

Off-site Troubleshooting and Consulting

Diagnostics and Testing

Fit, Finish, Electrical Soundness, and Dialectic Integrity Inspections

Surge Test @200% of Determined Original Value

Hi-Pot test and Core Loss/Loop Test

Megger DLRO 10X Digital Low Resistance Ohmmeter Polarization Indexing

Monolithic Industrial DC Bar to Bar Armature Commutation Tester

Data Acquisition System and Reports

Large Motor Capabilities

11 Motor Test Stand Capable of 240 VAC-4000 VAC and 0-600 VDC

Shop Test Equipment consists of one Baker Hi-Pot Testing Machine D24000

Core Loss Tester is a Lexseco Z00KVA Model 2200